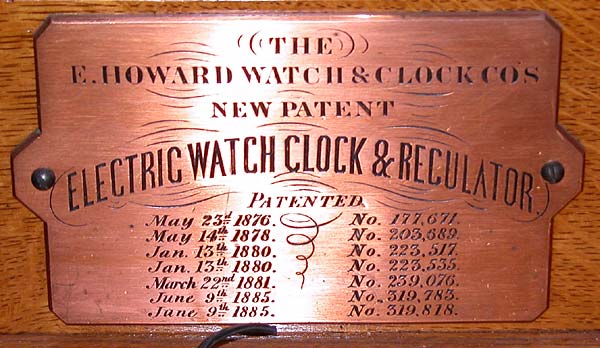

Being the first American clockmaker to produce electric time systems, E. Howard & Co. of Boston, Massachusetts deserves special recognition on these pages. With our focal point remaining The Standard Electric Time Co., it is interesting to compare the products of these two companies which, during much of the most intense period of their competition, were located less than 100 miles apart.

Howard's entry into the field of electrical horology apparently began with its successful manufacturing and marketing of strictly mechanical "Watch Clocks, for the Detection of Delinquent Watchmen on Night Duty in Factories, Railroad Stations and Public Buildings" ---1874 catalog. The catalog describes these early watch clocks as follows:

"The clock has a Time Dial (independent of the Pin Dial), which serves as a good regulator for time for the whole establishment.

"The Pin Dial is securely enclosed, so that it is impossible for it to be tampered with, or the pins driven (other than by the regular pulls), without immediate detection.

"The clock should be placed in a room convenient for the exhibition of time, and cords and pulleys run from the clock to such rooms or places on the premises as you wish the watchman to visit each HALF HOUR of the night. Care should be taken that the termination of the wires should be in such places as to cause the watchman to explore as much of the premises as possible. It is necessary to visit all the rooms or places designed in order to drive ONE PIN. The clock is so constructed that fifteen or twenty minutes (according to the number of rooms that have to be visited,) is allowed the watchman to go over the building. With this clock the watchman cannot fail in his duty without detection."

The same catalog then goes on to introduce the "Electro-Magnetic Watch Clock":

"MR. J. HAMBLET, JR.,

Electrician and Inventor of this Clock,

"Is now associated with us, and will devote his attention to the manufacture, sale and erection of these clocks.

"The Watch Clock is used in all Manufactories, Railroads, Lumber Yards, and all places where watchmen are kept during the night. The clock may be placed in the office, or in a separate building at a distance from the premises to be guarded. A system of wires radiates from the clock to all buildings and premises, and to the points which it is desirable for the watchman to visit in his tour of duty. At each point or station the watchman inserts and turns a key, or simply touches a knob, which causes the electric current to pass and do its work upon the magnet at the clock, and cause a pencilled record on a PAPER DIAL at the exact instant when the key is turned. The watchman in this manner, passing around from station to station, successively, makes TELEGRAPHICALLY his own record of duty done, showing the time of each visit to each station, as well as the time occupied between the stations; and of course the whole time taken up in making the entire round, and also in going all the rounds; and if all the stations have been visited or have been neglected the facts will be shown upon the dial. In fact the Superintendent can read in the morning the exact part of the premises at which the watchman was at any minute of his required tour of duty during the night.

"The paper record dials are changed daily, and may be filed and kept as a permanent record of the watch duty, INTERESTING TO INSURERS, being the time record made by the watchman himself, and which he can make in NO way except by visiting the stations in regular order."

Because of public skepticism at that period concerning all new things electrical, the strictly mechanical watch clocks remained popular a while longer, until the superiority of the electromagnetic version became well established. But even before then, Howard had developed and begun installing the the master/slave type of clock system destined to become practically universal in schools and other large public buildings. Prior to 1884, the year The Standard Electric Time Co. claimed that its founder, Charles D. Warner had invented the electric clock, Howard had actually installed a number of electric time systems in various prominent buildings. Some of these buildings were named, along with the year of installation, in a circa 1900 Howard catalog:

Boston, Mass., Park Sq. R. R. Station, 1874

New York City, New York Tribune Bldg., 1875

Lansing Mich., State House, 1878

Hartford, Conn., State House, 1878

Boston, Mass., English High School, 1880

Nashua, N. H., Nashua Mfg. Co.'s Mills, 1880

Pawtucket, R. I., Conant Thread Co., 1881

New York City, Cooper Institute, 1882

New Orleans, La., Cotton Exchange, 1883

For a master clock, early systems such as these relied on either a hand-wound, weight and cable-driven regulator or tower clock movement. The electrically-wound master regulator came later.

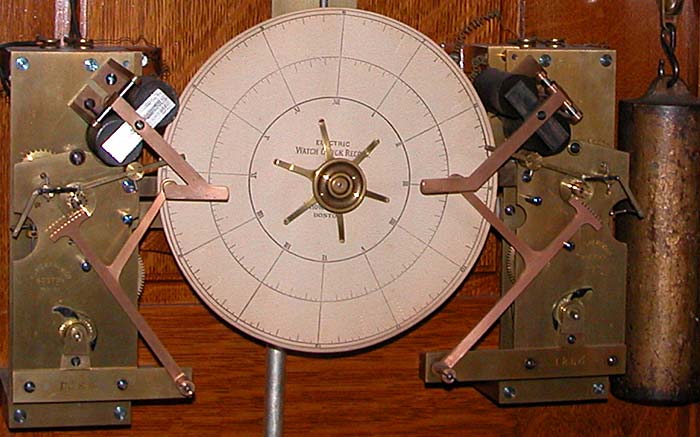

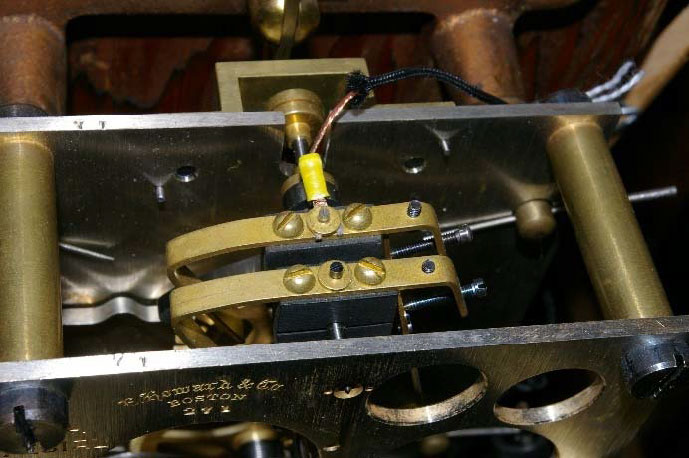

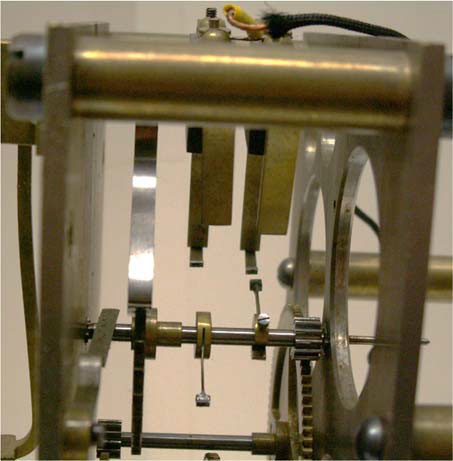

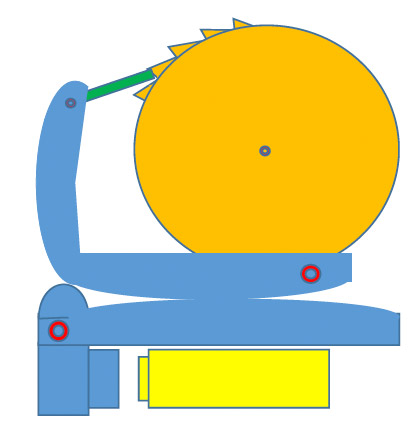

Early Howard secondary clock movements, like those of Chester Pond, used

electromagnetic energy to directly drive the hands as the armature pulled

in. Although logical, this method proved inferior to the later idea of moving

the hands by means of a spring energized by the magnet. While the later Standard

Electric Time Systems proved themselves electrically superior to Howard's,

the longevity attained by Howard's construction method utilizing numerous

beautifully machined parts in place of thinner sheet metal stampings, is beyond

reproach. With respect to design, of particular note is a 2-lever power equalizing

system the company employed in both electrically-wound master clock movements

and

those of their improved secondary clocks.

Source: Illustrated Catalogue of CLOCKS manufactured by the Howard Watch and Clock Co. (E.Howard & Co. Proprietors), BOSTON, 1874; reprinted 1972 by the American Clock and Watch Museum, Inc., 100 Maple Street, Bristol, Conn. 06010

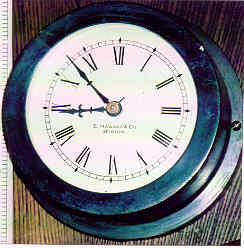

This clock was discovered hanging idle in the periscope shop at Puget Sound Naval Shipyard over 30 years ago by clock enthusiast and submarine radioman, Ernie Lopez. The periscope shop had once been the chronometer repair shop and the Howard had served as the master clock. Many years later Ernie enlisted the assistance of the author and Leon Jaussaud another local clock enthusiast to rescue this very significant instrument. Negotiations ensued with the Navy and eventually this clock along with two other significant shipyard timepieces were restored and placed on long term loan with the Kitsap History Museum.

The original mercury pendulum was intact but without mercury. It was surrounded by a stainless steel

enclosure and the case showed signs of a mercury spill and cleanup effort. Ernie Lopez completed a

painstaking restoration of the case and Leon Jaussaud did a masterful job restoring the movement,

pendulum and massive cast iron back plate. We were excited to note the large bronze plaque pictured

above connecting the clock to Joseph Mayer whose two street clocks we had recently restored for the Kitsap County Historical Society. We believe Mayer installed this clock system at the shipyard in about

1915. It probably controlled one or more slave clocks similar to the one pictured.

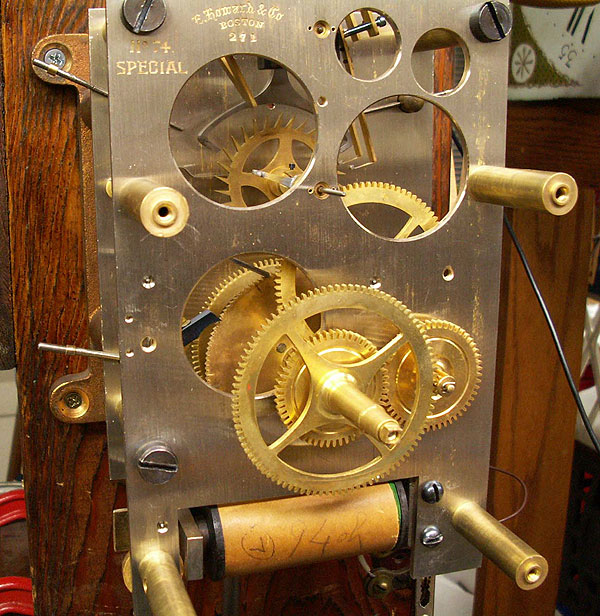

We were quite excited to be dealing with something of this quality and technical excellence but this clock did not match the traditional Howard No. 74 in any way. Subsequent inquiries of Howard collectors and experts yielded no information on this clock.

The movement is based on a No. 89 electrified to be wound electromagnetically once per minute.

Howard developed this movement in about 1904 or 1905. It was used in conventionally dialed master

clocks and domestic tall clocks.

This movement is identical in every way to the electrified No. 89 though it is carefully engraved "No. 74 Special". The only things that distinguish the clock from an electrified No. 89 are the dial configuration and the very heavy cast iron dial plate. The dial has been repositioned on the movement so the escape wheel arbor comes out at the center and is fitted with a sweep seconds hand. The hour and minute dial is relegated to a position below the center.

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

Jeffrey R. Wood, creator of the Standard Electric Time Co. (SETCO) pages of clockhistory.com, passed away in August of 2018. I will maintain the SETCO web pages in honor of Jeff, but will not be making any additions or changes, or answering any questions. It is hard to express how much I miss Jeff, his friendship, and his wonderful contributions to Standard Electric and Westclox research.

Bill Stoddard