|

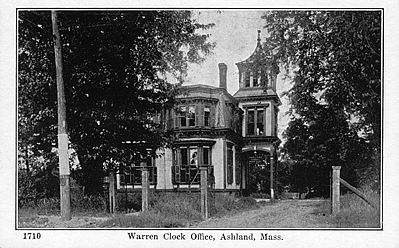

Postcard, date unknown |

Henry Ellis Warren enjoyed experimenting with and designing electric clocks and applied for his first patent in 1908. It was granted as #927,907 on July 13, 1909 and titled "Electric Apparatus for Driving Clock or Similar Mechanisms." It covers a battery driven pendulum clock where an electromagnet impulses the pendulum. Warren made many improvements to his design, and received at least six more patents about electromagnetically impulsed pendulum clocks. His work with electric clocks had started as hobby, and in 1912 he formed the Warren Clock Company but kept his regular job as superintendent of a manufacturing company. In the next few years, a small number of Warren's electrical pendulum clocks were marketed.

In 1916 Mr. Warren recognized the inadequacy of battery powered clocks, and began exploring other possibilities. He desired a simple system which would have universal application, and considered the two great networks which were then available: the telephone system and the electric light and power lines. The electric network appealed to him strongly because it not only carried enough power to drive clocks, but it contained timing information carried by current reversals. At that time, 90% of electric power was "alternating current" (A/C) which reverses direction many times each second.

By the summer of 1916 Mr. Warren had developed an A/C powered synchronous motor suitable for driving clocks. The term "synchronous" comes from two Greek words meaning "equal time". This motor stays in step with the reversals or alternations of the A/C current. These motors are inefficient, but develop more than adequate power to drive a clock.

After developing a clock motor, Warren's next task was the regulation of the alternations of the A/C current. A/C power in the United States is referred to as "60 cycles per second" or "60 Hertz" power because the current reverses direction 120 times each second, and each pair of reversals is called a "cycle". (In the early days, some power systems in the US used a frequency other than 60 cycles per second). In 1916 the number of cycles per second was not well controlled (there was no reason for it to be) and thus Warren's electric clocks had errors of up to 20 minutes per day!

To solve the problem, two things were necessary: an instrument that could conveniently be used by power station attendants for regulating the frequency of the alternations; and second, creation of a state of mind among the power company managers that would justify them in giving this new service to the public. It took Warren only a few months to design and build a satisfactory master clock, but several years to convince the power companies to adopt his master clocks.

Mr. Warren applied for a patent on Aug. 21, 1916. This patent was granted on Oct. 29, 1918 as #1,283,431. It describes a system where the time on a synchronous clock is compared to the time on a standard regulator, and a control means for correcting the speed of the generator so the average speed is 60 cycles per second, thus keeping all synchronous clocks on the power line on the correct time.

This patent also illustrates and describes a synchronous motor for driving the electric clocks. This motor looks like what was named the type A motor , the first motor that Warren Clock Company put into production. The patent also describes an auxiliary movement for the synchronous motor clock that will keep the clock on time if the power is interrupted.

The two most common master clocks used by power plants were the type A and the type B. The type A master clock is a floor standing unit. It is described in patent #1,502,493, applied for on April 15, 1918 and issued on July 22, 1924. The type B is a smaller unit that hangs on the wall. It is described in patent #1,502,494, applied for on April 2, 1920 and issued July 22, 1924.

Around 1919 or 1920, the type B motor was introduced. It used a sealed housing for the moving parts, and the design was so good that they ran for many years without attention. The sealed housing portion is called the "rotor" and the electrical portion is referred to as the "field coil assembly".

The Telechron trademark was registered on November 13, 1923, applied for on March 3, 1921, but was first used in December 1919. The trademark Telekron (with a "k" instead of the "ch") has been observed on a few early clocks. "Telechron" comes from Greek words meaning "time from a distance".

"The growth in the sale of these modern electric clocks was very gradual after the first system became available in 1916. Only a few thousand were sold each year for the next three or four years. By 1921, however, the success of those in use and the publicity which followed stimulated sales to a point where manufacturers of other kinds of clocks began to take notice, but it was not until 1927, ten years after the system first became available, that forms of synchronous electric clocks other than the ones which I have described to you began to appear on the market. Then a group of rival manufacturers began to grow and within a few years there were over a hundred different concerns which were selling synchronous electric clocks intended for use on systems that had been established quite generally throughout the country. Nearly all of these new forms differed from the original type in that they possessed no starting power, that is to say, it was necessary to start them manually and whenever there was an interruption in the power supply they would stop and not run until they had again been started by hand. While they were running they kept just as good time as the original type of self-starting synchronous clocks, but most of them were defective in some respect or other so that within another period of a few years they began to disappear from the market. Most of them were noisy, nearly all were short lived, and the universal habit of stopping after every power interruption proved to be a nuisance in many cases."

"You will notice that the Telechron clocks of which there is a display in this room are provided with an indicating device so as to give a signal after an interruption. Such interruptions, of course, make an error in the time indicated by the clock equal to that of the interruption. Generally speaking interruptions are short so that the warning signal is sufficient for most purposes to take care of the usual interruptions in the current. When it becomes very necessary to eliminate the effect of interruptions, as in public building installations and some other places, Telechron clocks are built with either sustaining mechanisms which keep the hands in motion during an interruption or with resetting apparatus which automatically measures the length of an interruption and then after the current returns moves the hands forward to make correction."

In the 1930's, motors type F and type H were introduced. These are smaller than the type B, and were also very long lasting. The type F was made for a relatively short time, but the type H became the most widely used motor of all for domestic clocks. The type B continued in use for many years in chiming clocks and specialized devices such as timers. A smaller motor, type S, was introduced in the 1970's or 1980's and was the last type to be used in new clocks.

These motors are no longer being made. Donations of old

rotors and clocks (even non-working ones) will be gratefully accepted. These

will be used for research purposes, or the parts can be used for rebuilding

other rotors. See our contact information at the bottom of the page.

See these other web sites for

more information about Telechron |

|

| Pappy's Telechron Clock Page | Telechron Master Clocks and Time distribution |

The quoted areas in the text are from the Proceedings of the Boston Clock Club, February 6, 1937 "Modern Electric Clocks: A paper read by Henry E. Warren" . Other information is from that paper as well.

United States patents 927907; 1283431; 1283432; 1283435; 1430,867; 1502493; 1502494. See our patent web page for more Warren and Telechron patents.

This Clock Made Powwer Grids Possible, IEEE Spectrum, February 29,2024.