Charles Stahlberg's patent of Sept. 22, 1885 describes the basic process used to make United Clock Co., Western Clock Mfg. Co., Western Clock Co. and Westclox clocks. To make a wheel and pinion assembly, steel pinion and pivot wires and the brass wheel were held together in a jig while a molten lead alloy was poured in. Then the lead alloy solidified, holding the steel and brass parts firmly in place.

The earliest clocks have their balance wheel rims made of the lead alloy, but by 1900 normal brass balance wheels were in use. The patent also describes casting the movement plates from this lead alloy with inset brass bushings! No clocks with this construction have come to our attention yet.

The September 22, 1885 patent date is stamped on the back of most of the clocks made before 1903, when it was replaced by the October 28, 1902 patent date.

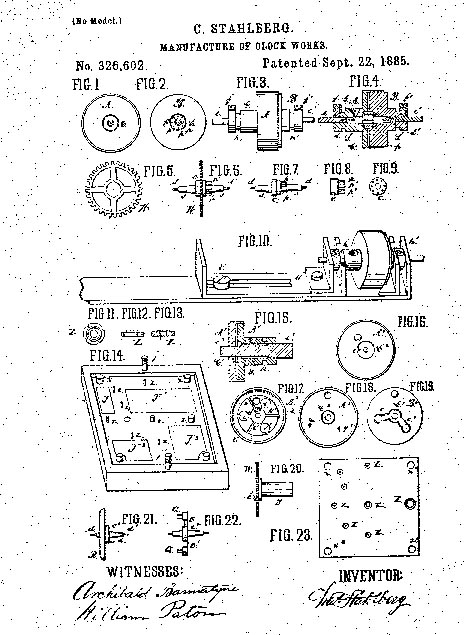

Here are some excerpts from the patent:

"Be it known that I, Charles Stahlberg, a citizen of the United States, residing at Waterbury, in the county of New Haven and State of Connecticut, have invented certain new and useful Improvements in the Manufacture of Time-Pieces and Clock-Work Mechanisms, of which the following is a specification, reference being had to the accompanying drawings.

"My invention relates to clocks and kindred mechanisms where resistance to wear and accuracy of construction are required; and it consists in making the parts of the same -- such as wheel-shafts, pinions, socket-wheels, balances, verges, and plates -- by casting their body portion of an alloy which expands on solidifying around or into extensions or recesses of hard-metal acting portions, whereby such portions -- as pivots, pinions, pallets, bearings, wheels, &c. -- of brass, steel, or other hard metal, are clamped and held in position by the above-mentioned alloy, which latter forms the remaining portions of the finished part.

"The alloy used should contain antimony or bismuth, preferably both, to give it hardness and the quality of expanding on solidifying. Type metal, to which a little bismuth is added answers well. Most any alloy which has a comparatively low melting point and possesses the property of expanding on solidifying will answer my purpose.

"The movement-plate, Fig. 23, is of alloy. Brass bushings for bearings are embedded in the alloy in a manner as before shown. x, x', x'', and x''' are holes for pillars. z, z', &c. are brass bearings embedded in the alloy."